Municipal water treatment

Magnetic media for water treatment / Denitrifying deep bed filter equipment / Improving BD Biochemical Tank Equipment / Low temperature belt type sludge drying machine / Magnetic media for water treatment / Automatic magnetic medium feeding machine

Products & Technology

Low temperature belt type sludge drying machine

Process Introduction

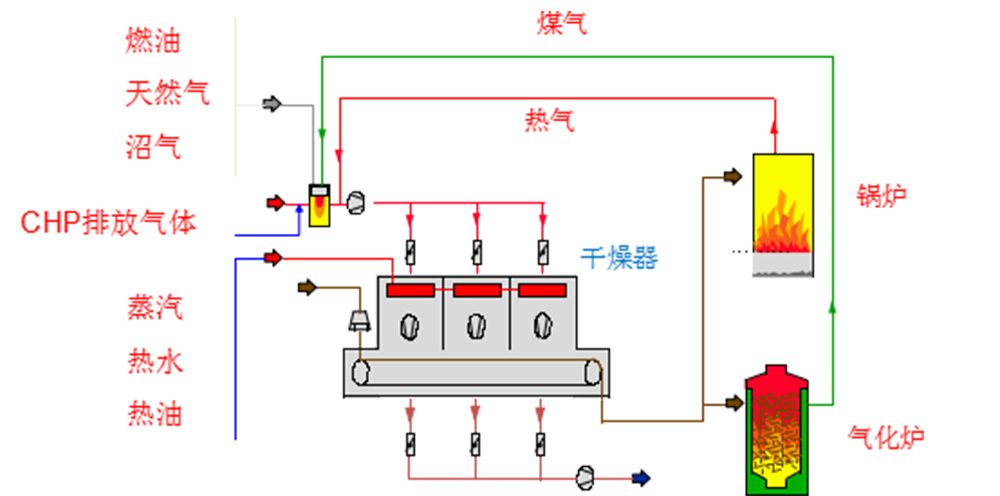

The low-temperature belt type sludge dryer adopts convection drying technology, and the main working principle is to use dry hot air as the drying medium. It continuously contacts with the sludge through a circulating fan to take away the moisture in the sludge. The high-temperature gas is then condensed through cooling water to achieve the drying purpose. The entire process is in a fully enclosed form, with no odor overflow.

The main components of the system include: wet sludge forming machine, drying room, conveyor belt, fan, heat exchanger, wet sludge silo, dry sludge silo, sludge conveying device, waste gas treatment device, and automatic control system. This equipment is an environmentally friendly, efficient, and energy-saving sludge drying machine that can dry wet sludge with a moisture content of 85-60% to below 10% (adjustable moisture content of 50-10%), thereby achieving reduction, stabilization, and harmless treatment.

Technical characteristics

1. There are a wide range of heat sources that can be used, including steam, hot water, heat pumps, natural gas, biogas, flue gas, and other heat sources;

2. The temperature range of the drying zone is 80-140 ℃, with low temperature and low energy consumption;

3. No visible dust is generated, with a particle size range of 3-5mm and a dust content (particle size of 0.3mm) to weight ratio of ≤ 0.1%;

4. Simple control and strong operability, the two main control parameters, namely the temperature of dry air and the residence time of the product, are easy to control and handle;

5. Strong safety, due to the low temperature and open-loop air processing method, the concentration of dust and combustible gases is low, and there is no risk of explosion. Therefore, the explosion-proof level of the system is Exia;

6. Simple maintenance, low maintenance costs, and low-speed moving components reduce maintenance costs.

Applicable scope

1. Suitable for drying treatment of biochemical sludge and inorganic sludge;

2. Flexible processing ability, can be semi dried or fully dried according to process requirements.

Previous Page

Next Page

Previous Page

Next Page