Municipal water treatment

Magnetic media for water treatment / Denitrifying deep bed filter equipment / Improving BD Biochemical Tank Equipment / Low temperature belt type sludge drying machine / Magnetic media for water treatment / Automatic magnetic medium feeding machine

Products & Technology

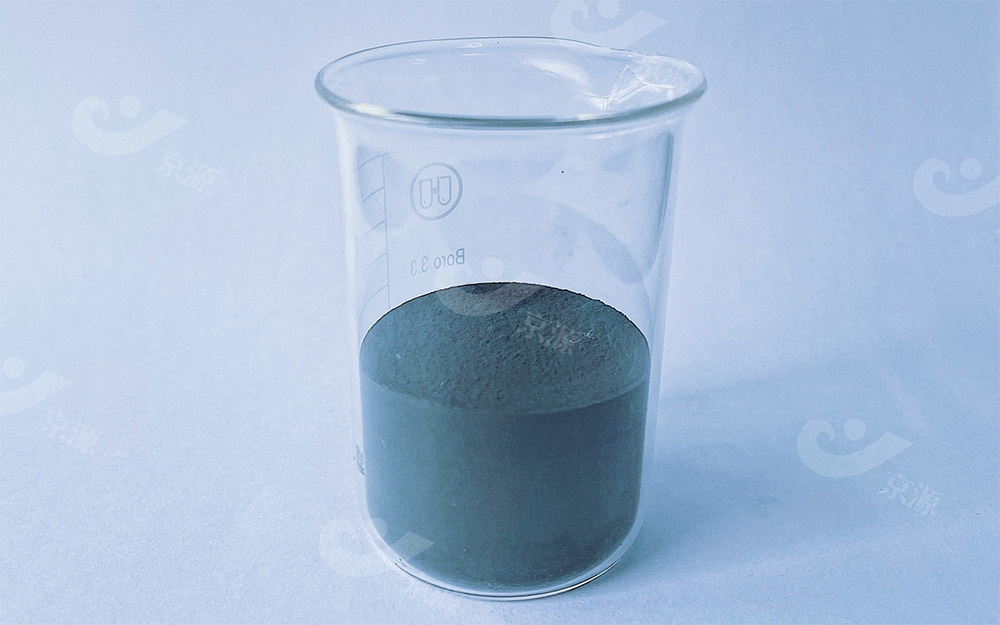

Magnetic media for water treatment

Product Introduction

Magnetic media for water treatment are also weighed in the market, including media powder, magnetic seeds, magnetic media powder, or magnetic powder. It is a key core material of magnetic medium coagulation precipitation technology, a black powdery fine particle solid, mainly composed of ferric oxide (Fe-O ₄), with a magnetic content of ≥ 92%, a moisture content of ≤ 12%, a sieving rate of ≥ 70% within the standard particle size range, and a true density of ≥ 3.5g/cm ³, Insoluble in water, acid, alkali, and organic solvents, non-toxic and harmless, with a stable chemical structure, and can be reused for a long time.

Technical precipitation

The initiator and editor in chief of the group standard T/CAMIE 3-2022 for magnetic media used in water treatment. Jointly designed with the Chinese Academy of Sciences, the first fully automatic superconducting magnetic medium production line in China was put into production. Special formula, higher product purity, uniform particle size distribution, and better purification effect. The only one in China that has obtained US NSF certification and can be used for drinking water treatment.

application area

Special customized superconducting magnetic media can be used for drinking water treatment, including industrial wastewater, municipal wastewater, advanced treatment and reuse of reclaimed water, and river treatment.

Indicator parameters

| Specification classification (partial) | Particle size distribution range (mesh) | Particle size distribution range (micrometers) | |||||

| MAG -100 /200 | 100 ~ 200 | 74 ~ 148 | |||||

| MAG-100/300 | 100 ~ 300 | 49 ~ 148 | |||||

| MAG-100 /400 | 100 ~ 400 | 37 ~ 148 | |||||

| MAG-200/500 | 200 ~ 500 | 30 ~ 74 | |||||

| MAG-200/600 | 200 ~ 600 | 25 ~ 74 | |||||

| MAG-300/600 | 300 ~ 600 | 25 ~ 49 | |||||

| Note 1: Special specification requirements should be customized according to user needs. Note 2: The sieving rate within the particle size distribution range should reach or exceed 70%. Note 3: When using micrometers to indicate particle size distribution, the following formula is used for conversion: magnetic plasmid diameter( μ m) =14832/mesh. |

|||||||

| Indicator items | Indicator requirements | |||||

| first-grade products | Secondary product | chemically pure reagent | ||||

| Natural packing density, g/cm³ | 2.0 | 1.8 | 1.6 | |||

| True density, g/cm | 4.0 | 3.8 | 3.5 | |||

| moisture content,% ≤ | 8.0 | 10.0 | 12.0 | |||

| Screening rate,% ≥ | 90.0 | 80.0 | 70.0 | |||

| Uneven coefficient, dimensionless ≤ | 10.0 | 18.0 | 25.0 | |||

| Magnetic content,% ≥ | 96.0 | 94.0 | 92.0 | |||

| Note: Special specification requirements should be customized according to user needs. | ||||||

Previous Page

Previous Page